Featured Post

From data silos to cloud systems: the right move for your business

The Food & Beverage industry is constantly changing, and so it is important that companies can extract data at any given moment to make prompt business decisions. The failure of legacy systems to keep up with these needs for F&B manufacturers is entirely predictable – in fact, most of the producers who employ these systems are aware that they are living on borrowed time and simply delaying inevitable problems.

Categories

From data silos to cloud systems: the right move for your business

The Food & Beverage industry is constantly changing, and so it is important that companies can extract data at any given moment to make prompt business decisions. The failure of legacy systems to keep up with these needs for F&B manufacturers is entirely predictable – in fact, most of the producers who employ these systems are aware that they are living on borrowed time and simply delaying inevitable problems.

Achieving global industry compliance through a powerful suite of software solutions

In the Food & Beverage industry, compliance is of extreme importance because of the nature of the manufactured products. If companies are not compliant, food and beverage products directly affect the health of the consumer. In other words, businesses have a moral obligation to be aware of what goes into the production and sale of the products.

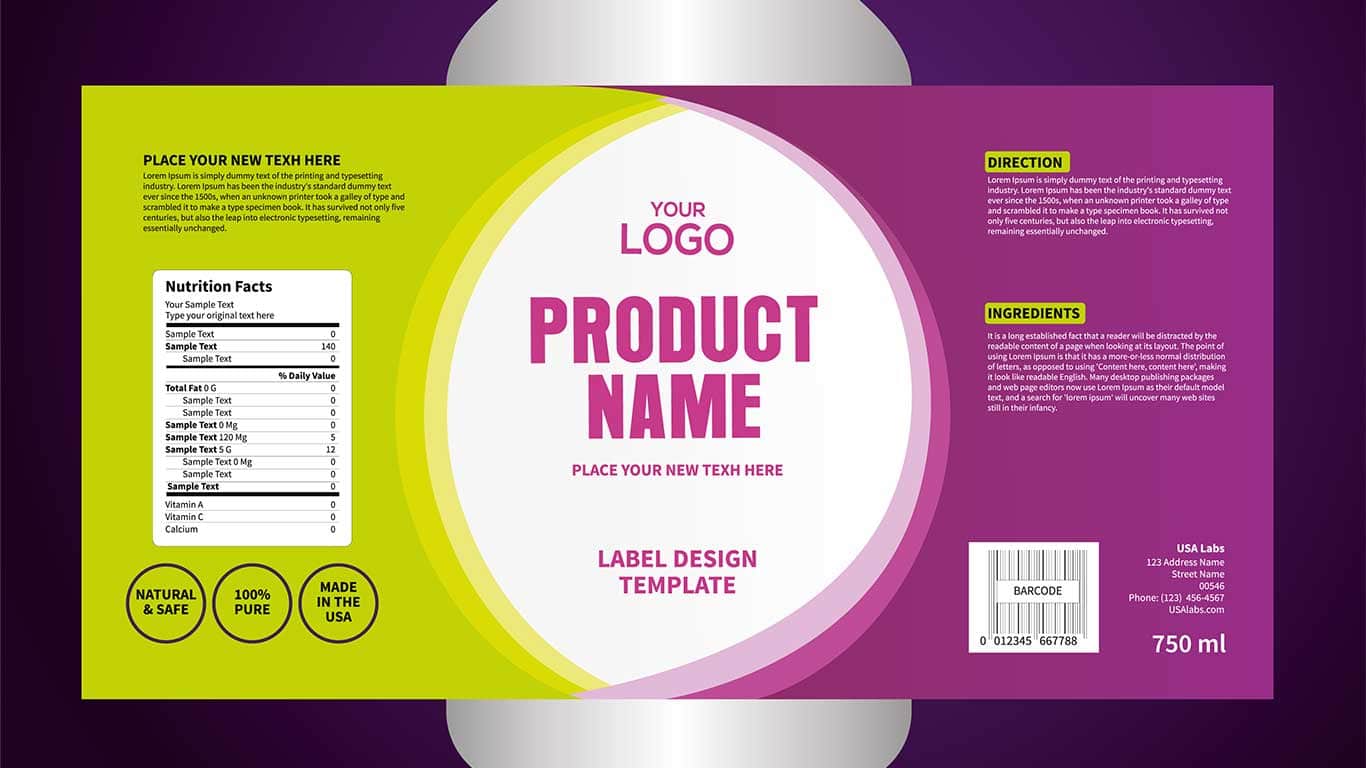

Managing the complexity of package design with PLM

With any product, packaging is important. It encloses the product and keeps it safe, it lists the informative details in regards to the product, and perhaps most importantly, it is the first thing your customers see and engage with.

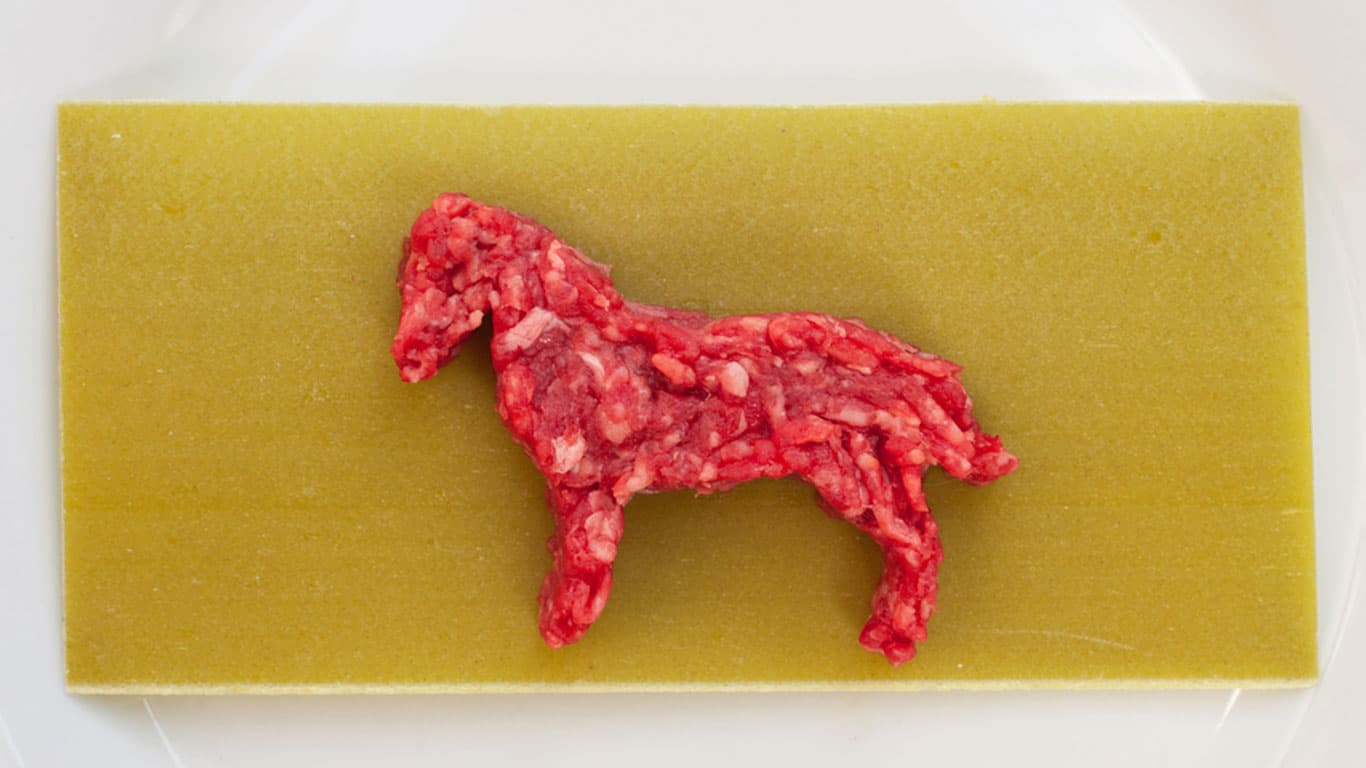

Food fraud: Protect your consumers and your brand

Food fraud started around the turn of the century when food production and supply industrialized. The Oliver Twist era brought us sawdust sold as hot dogs and other highly publicized scandals. Food fraud, the misrepresentation of a product through cheap substitutions of ingredients, was a way to stretch out a food’s primary ingredients while maximizing profits, at the expense of public health.

On the frontline of food defense: The fight against food fraud – and how PLM can help manufacturers guarantee transparency and compliance

Food Safety Net Services (FSNS) defines food fraud as: “the act of purposely altering, misrepresenting, mislabeling, substituting or tampering with any food product at any point along the farm–to–table food supply–chain. Fraud can occur in the raw material, in an ingredient, in the final product or in the food’s packaging.” From the 1981 olive oil scandal, where the hazardous chemical aniline, mixed with rapeseed oil, was masqueraded as the coveted oil by street vendors across Spain, to the 2013 horsemeat scandal in the UK, throughout history consumers have had more than enough reason to think twice before believing everything they read on the packaging.

AI Chefs

The most brilliant chefs can suggest flavor pairings that are all at once unexpected and yet effortless. Now, AI technology can do the same. New startups are emerging to help FMCG companies and large restaurant chains meet consumer demands.

Reducing tedious data management by implementing effective ERP tools

Companies generate large amounts of data on a daily basis. Each transaction that takes place between a company and its stakeholder needs to be recorded with extreme care to allow for traceability and transparency– which are crucial components for success in the Food & Beverage industry.

Culinary tourism at home: “travelling” via international flavors and innovative virtual experiences

Among many things that were affected by the global pandemic, a big one was tourism – but what does that have to do with the food industry? Well, what food experts are seeing is that many consumers are opting for global flavors to experience the world through an indirect form of “travel.”

Notable food trends of 2021, according to food experts

2020 saw big changes, that is no doubt. This year, many of the Food & Beverage (F&B) industry trends for 2021 are the result of these changes that were needed to combat the global pandemic. Health consciousness is a big consideration for food purchases, as well as the desire to have interesting and exciting food experiences while many of us are still stuck at home.

Coping with 2020: Comfort foods, cooking, and baking the new methods.

From sourdough breads to elaborate dinners, consumers across the world have adjusted to a life filled with more time in the kitchen. 2020 saw significantly increased sales at the grocery stores, with much of these sales being the target for recipes and comfort treats. Food and beverage manufacturers have greatly benefitted from this new consumer behavior, which was largely used as ways to cope with stress and increase productivity rates in the home.

Immune-boosting foods are the 2020 consumer’s new best friend

As a result of Covid-19, people have spent much of 2020 figuring out how to maximize their health in order to ward off any concerns they may have of becoming sick. In the food and beverage sector, consumers have taken a liking to healthy food that optimizes their immune system and reduces their vulnerability to the virus. The following are some of the trending habits that consumers have adopted this past year in order to calm their nerves and stay on top of their health.

The phases of food buying behavior in 2020: how the pandemic has influenced consumer purchasing decisions

The strain on supermarkets as a result of Covid-19 has given food and beverage (F&B) manufacturers and retailers many things to think about this year. Years of projected sales growth were packed into only a couple of months, and many of the usual consumer behaviors that they were observing had changed drastically.

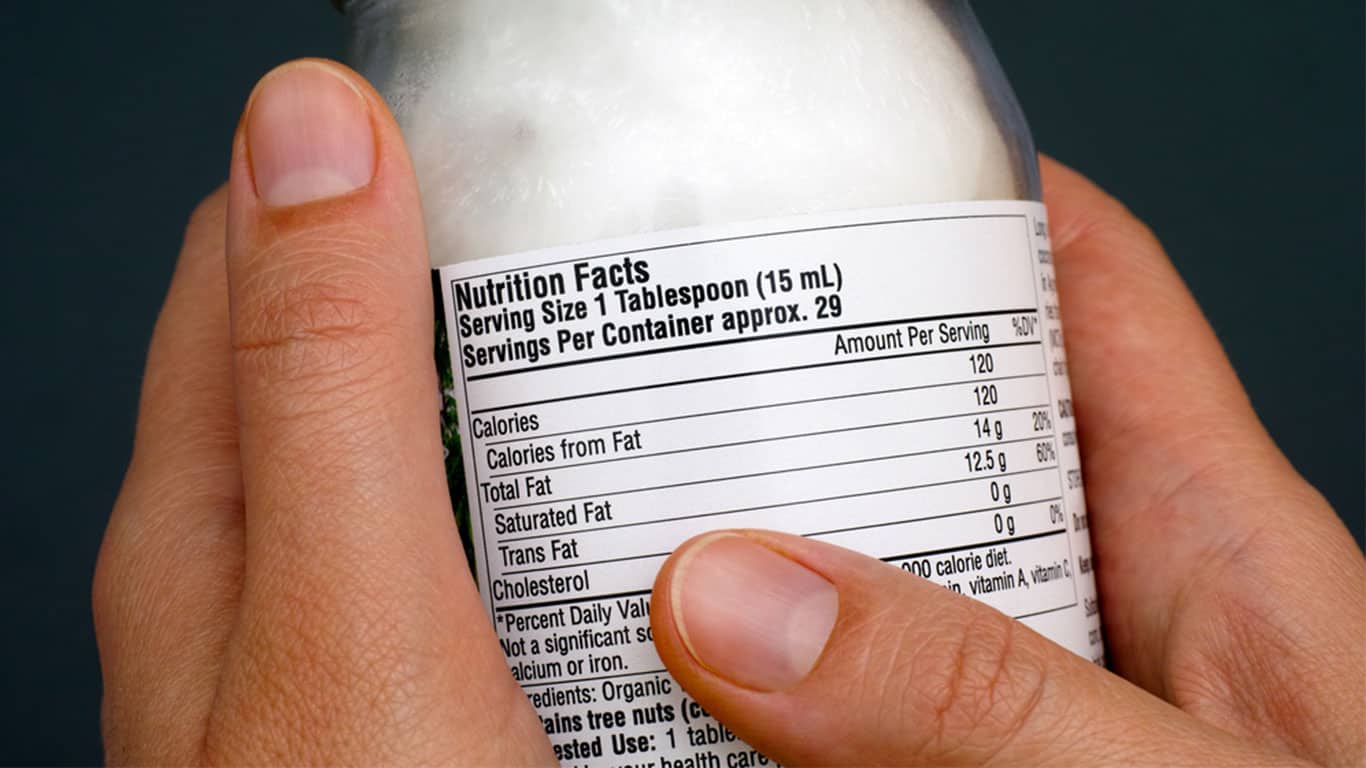

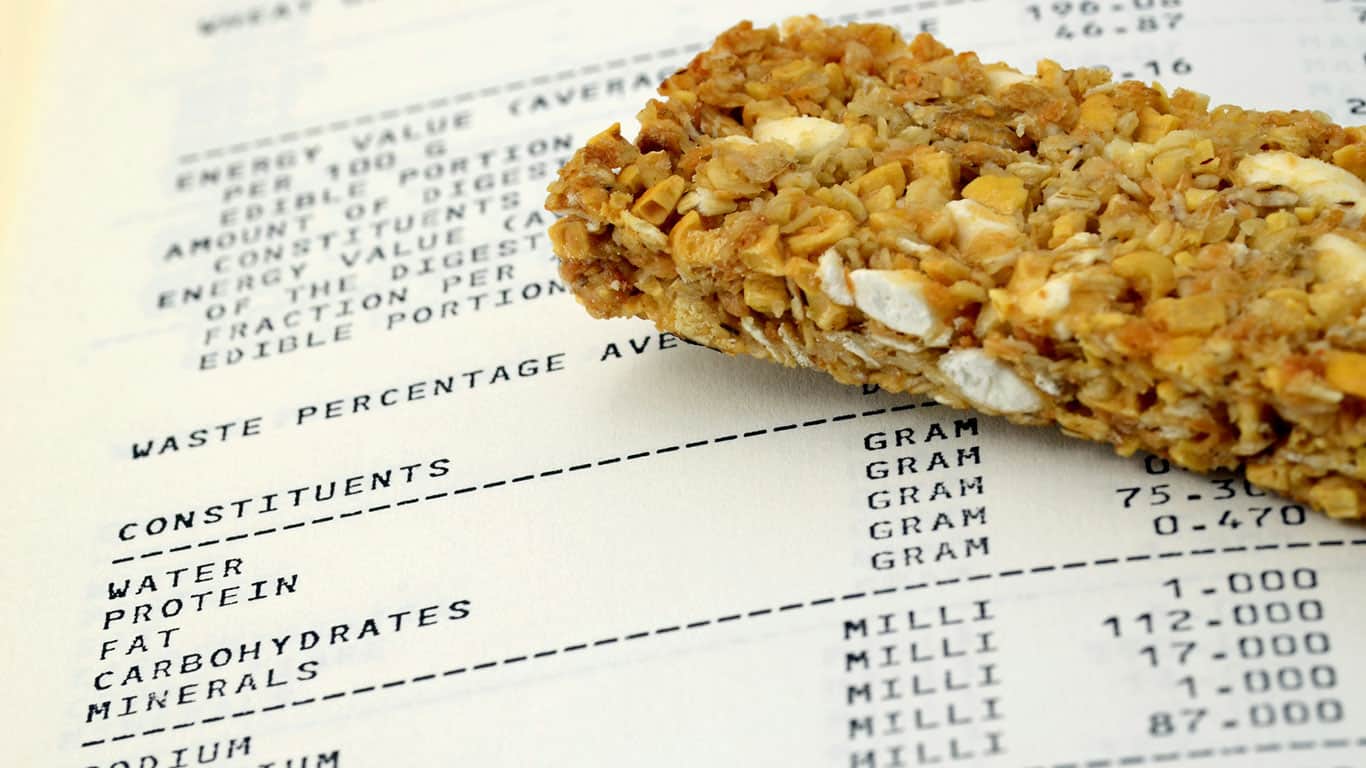

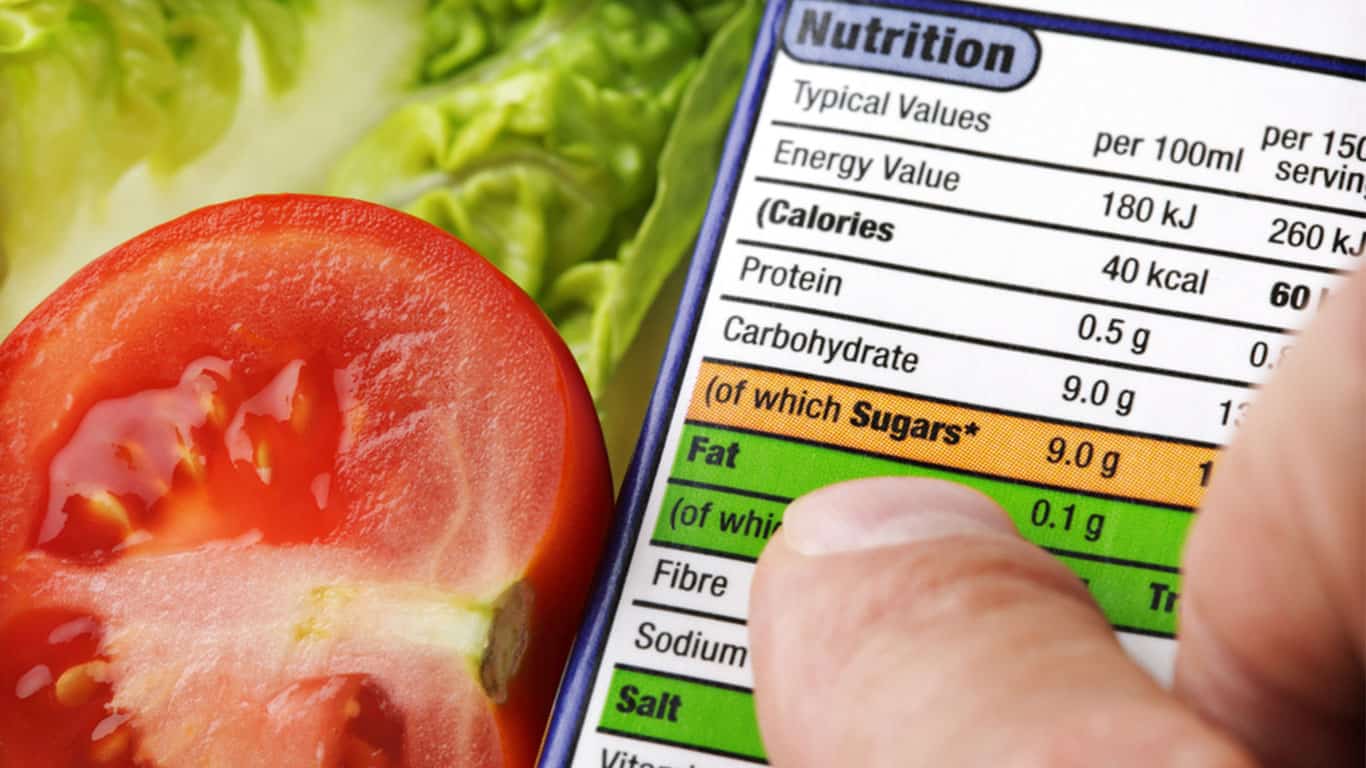

Navigating the challenges of a compliant food label

Among the many aspects of the food and beverage (F&B) industry that manufacturers must consistently adapt to, one very important aspect concerns food regulations. As science and food knowledge evolves, so too do governmental laws that protect the health of consumers by ensuring that there are standards for food safety on a national level.

The Clean-Label Challenges That Plant-Based Foods Face

Clean eating has gained in popularity in the past decade. Paleo, Keto, and other simple, whole-foods-based diet trends keep consumers searching for very particular sauces, seasonings, and pre-made meals when they’re not able to cook.

Sustainable Packaging, Part II: Eliminating waste by eating it

In our previous blog of this series, we learned that plastic packaging, though useful for food preservation, are harmful to the environment for their low recyclability rates; consumers are misinformed about effective recycling practices, biodegradable materials aren’t as compostable as assumed, and many plastics are not easily sortable. The end result? Less plastics that can be reused, and more plastics that are discarded in landfills.

Sustainable Packaging, Part I: The problem with plastics

Almost all the food that consumers buy – from produce to processed food – comes packaged, and quite a lot of the packaging is designed for single use. Plastics, which are used very often to encase food and beverage (F&B) products, have a lot to blame when it comes to recyclability, or lack thereof.

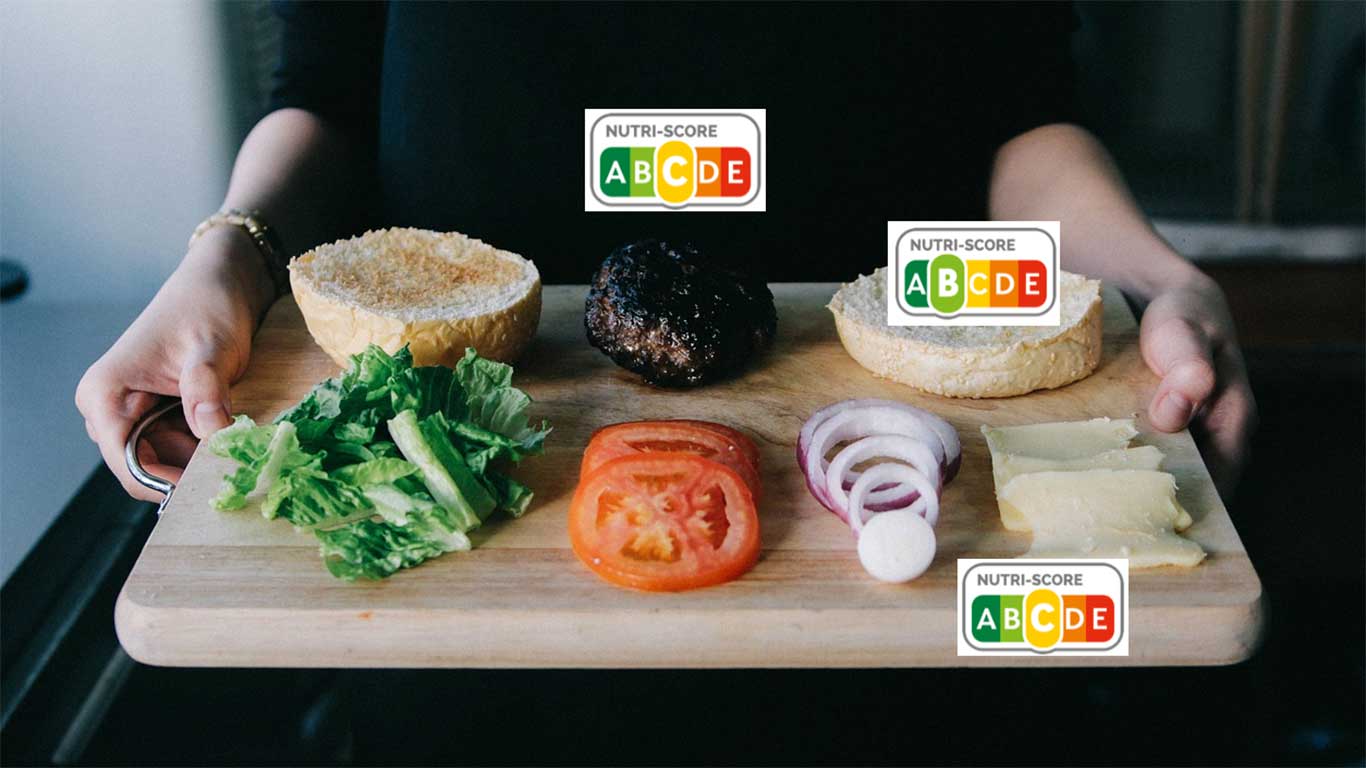

The Nutri-Score and its competitive advantages to achieve transparency

As one of the latest labelling practices to have hit the Food & Beverage industry, the Nutri-Score is making its way into food producers’ minds. “Should we use it? Is it effective? How will we benefit?” are just a few questions product innovators are asking themselves.

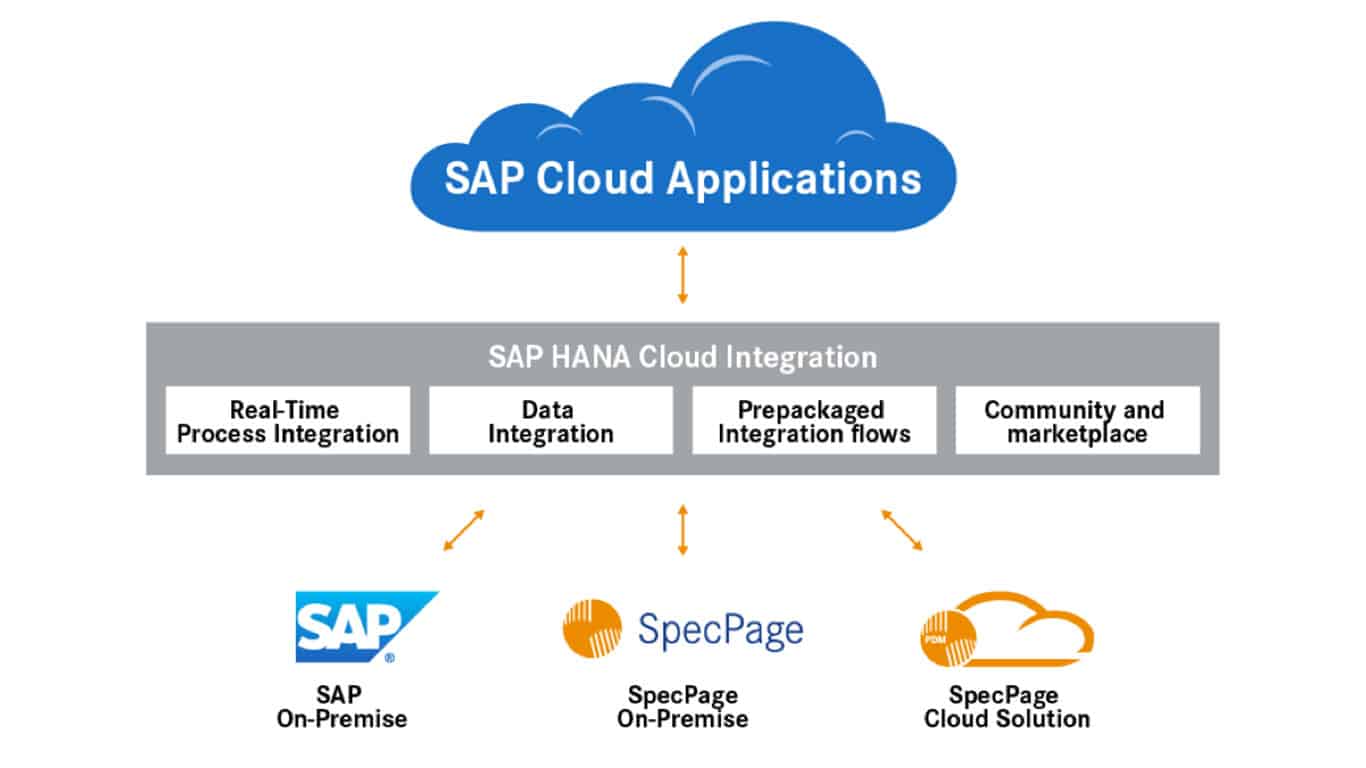

The growing appetite for cloud in food & beverages

In today’s technological revolution, cloud computing has been one of the more influential players. Though the F&B industry was slower to adapt to the cloud, F&B producers have now latched on with little intention of letting go. In many ways, cloud has proven to be a great technological asset, allowing companies to maximize their potential by improving general production and business processes of a work day. Today, manufacturers who have adopted cloud computing are reaping the many benefits it has to offer. Keeping the F&B industry in mind, we explore some of these benefits below - and encourage you to try the SpecPDM Cloud.

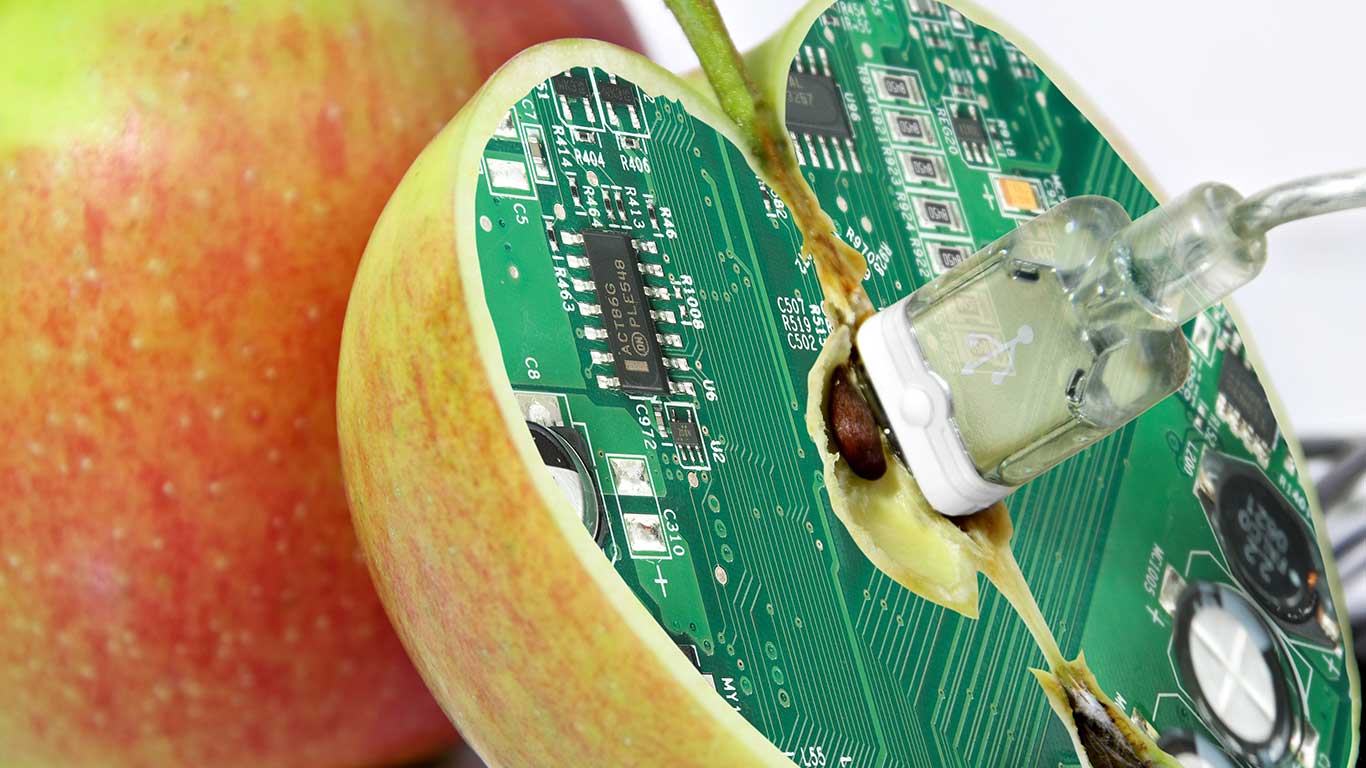

Intelligent packaging could be the Holy Grail for innovations towards the environment

There is a new environmental initiative that has hit the Food & Beverage industry of the EU, and its name is Holy Grail 2.0. Currently in September 2020, there are 85+ brands that have pledged to implement the Holy Grail project, some of which include F&B giants Pepsico, Henkel, Heineken, and Dr. Oetker.

Non-Animal Protein Product Design: New Innovations & Trends

An influx of new meat and dairy alternatives are taking over supermarket shelves for good reason. With dietary preferences and ecological stability in mind, more consumers are reaching for these alternatives than ever before. But they’re not settling for the same vegan options that have been available for decades. They want new, innovative flavors, better textures, and trendy alternatives. In this post, we’ll explore the demand behind this trend, it’s projected longevity, and the innovative products rising up to delight choosy consumers.

Consumers push for local and organic… and truthful labelling, too

In the last decade, organic food has steadily made its way into consumers shopping carts, as a priority to many. Even locally sourced organic food is increasingly sought out despite its higher price point – making it clear that consumers are willing to pay for healthier labelled products. While produce is the main focus for consumers’ organic purchasing, meats and dairy are also a concern for consumers; people want to be sure that their food does not contain the harmful pesticides or hormones that is often talked about in the food industry.

Crickets and Peas: The Market for Alternative Proteins is Growing by the Billions

As the alternative food market continues to boom across the world, the question that consumers and producers have on their mind is “what’s next?” Will another soy product take popularity again? Will oat milk gain favor over almond? Will pea protein be the thing to watch in 2021?

How to balance food quality & safety

Establishing a balance between food safety and food quality can be quite the feat in the Food & Beverage industry. Food safety and quality are not just dependent on the food producers, because there are multiple players who contribute to these aspects - from consumers, to regulatory agencies, to grocery stores.

Guide to Nutri-Score: Main Goals and Current Usage of the Food Labelling System

The Nutri-Score food system is getting rolled out throughout Europe. According to the European Commission decision, the motivation for this new food labelling system is “to guarantee that consumers are provided with quality nutritional information and to protect their health.”

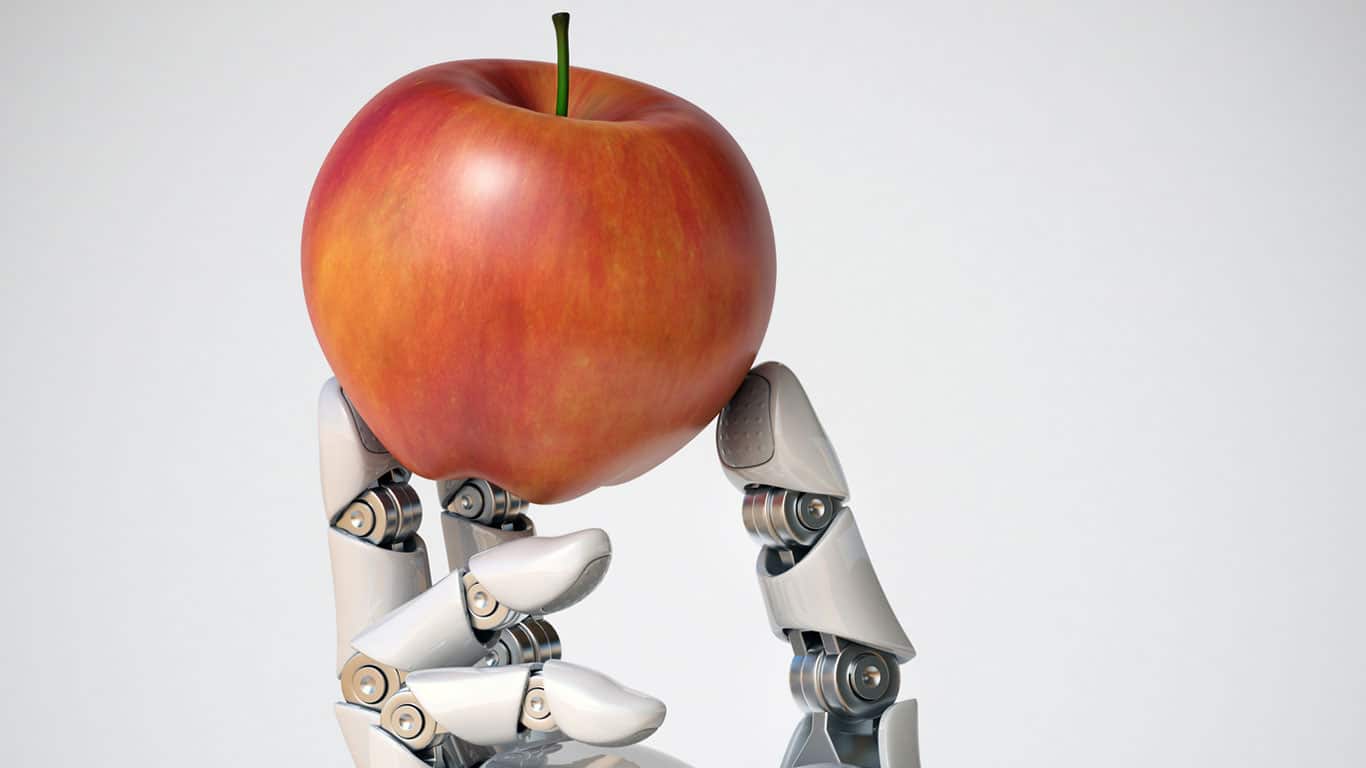

Powering Supply Chain Risk Management with AI

Move over chat bots. AI has countless applications besides taking humans out of the equation with sales and marketing conversations. While ecommerce is getting all of the AI attention from tech media, the food and beverage industry is quietly employing more AI every month: more applications, more use cases, more manufacturers and brands jumping on board, more startups entering the scene.

Maximizing Growth with Innovative Cloud-Based PLM: streamline processes and reduce costs

Cloud computing has changed the face of technology as we know it. Not only has it affected the way people interact on the internet, cloud has also changed businesses’ IT systems for the better. In fact, many companies who have adopted cloud-based product lifecycle management, or PLM, solutions have surged ahead of competitors.

How Food and Beverage Companies Are Implementing AI for Supply Chain Management

AI is growing both in the breadth of applications to supply chain management and the number of food and beverage companies utilizing it for everything from supply chain forecasting to customer visibility.

The Advantages of SaaS PLM When Working Remotely

SaaS PLM software allows your food manufacturing facility to continue working on multiple critical projects no matter where in the world individual employees are located.

Why Supply Chain Safety Needs to Ditch Manual Processes

Ensuring supply chain safety is critical for food manufacturers, but many companies continue to utilize the same outdated processes despite increased pressure from regulatory entities and consumers.

How to Remotely Implement PLM Software

A remote implementation of product lifecycle management (PLM) software might sound like a stretch, when in fact, SpecPage has been offering this for years.

Data Management key role in the Food and Beverage Industry

Ensuring product quality is one of the most important activities that businesses need to engage in. The first step here is to ensure that consistent reporting of all processes and materials used has taken place. Data management is useful in keeping all product-related records up to date.

Millennials Food trends – Smart Eating & Trust in the Label

Nearly 40 percent of millennials say that they will switch brands if promised more transparency. This is why so food producers that provide the most accurate and honest information win.

Food Innovations and Compliance

Innovation and compliance; how do they influence each other? Many food and beverage manufacturers struggle with restrictive compliance regulations – others with driving innovation without interfering with compliance procedures. The key to achieving both, is to maintain a relationship between these two factors.

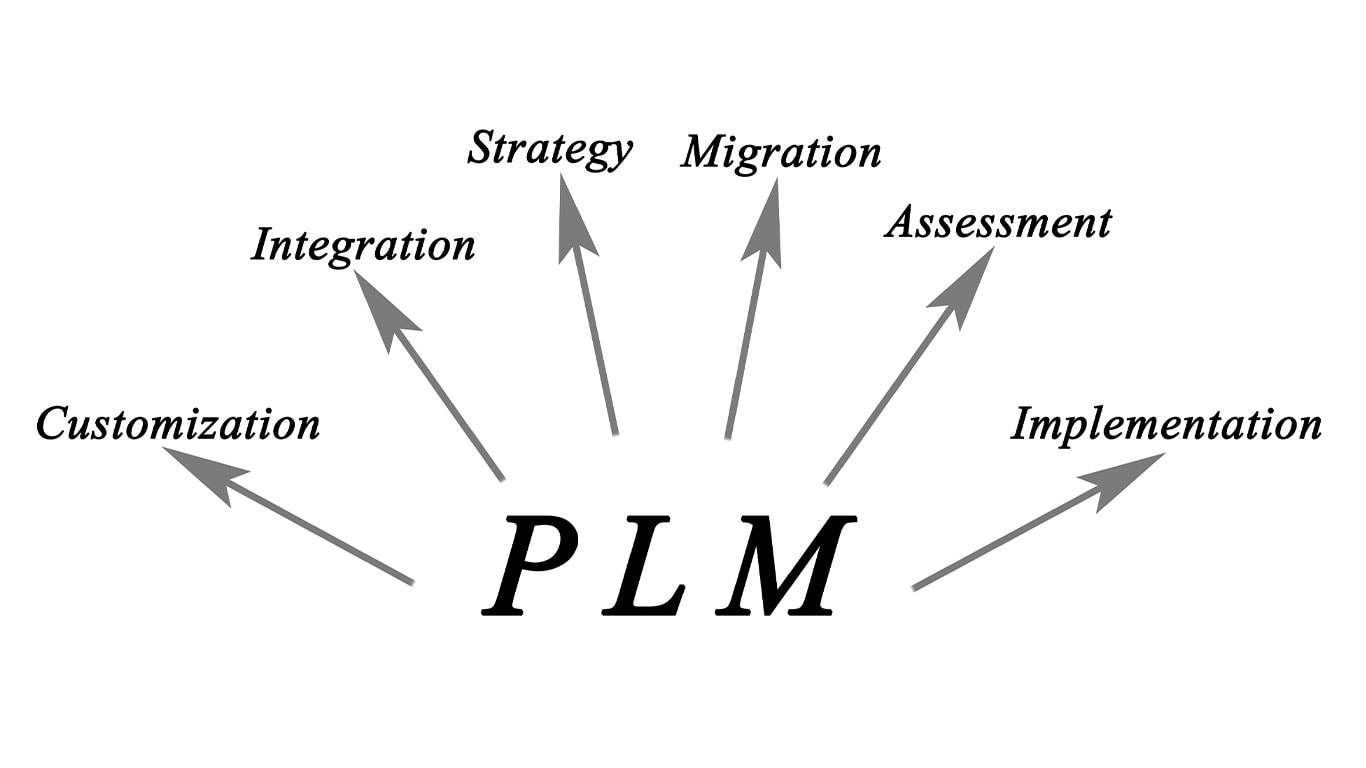

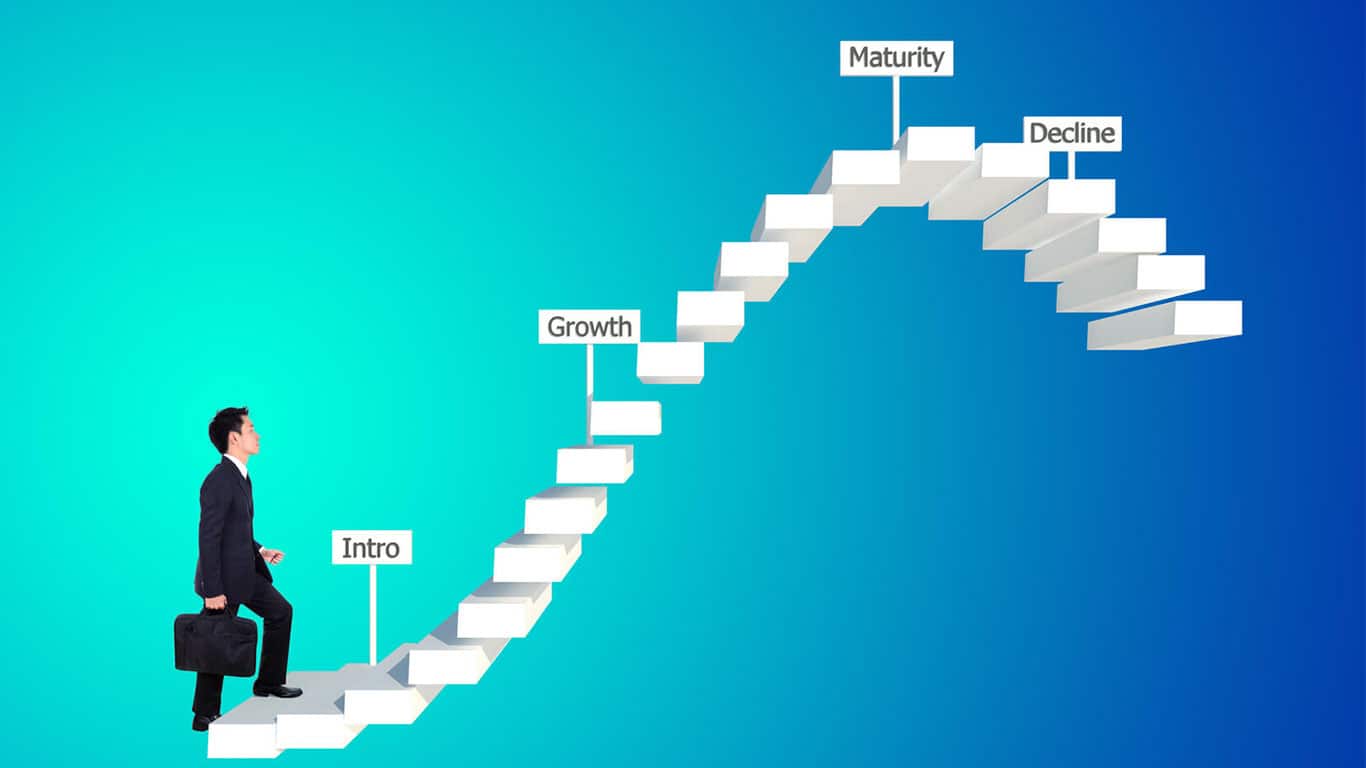

Product Lifecycle Management, and why you should have it

Product optimization is best achieved when there is a focused attempt at controlling associated costs and quality in all stages of development. This is where product lifecycle management is fundamental: by managing all the processes and activities involved in new product development, organizations can ensure that the final product released to market is of high quality and low in cost.

The 4 G’s for product data management GDSN, GS1, GTINs and GLNs

All of us have heard about the 4P’s of Marketing. How about extending this concept to the world of data synchronization between trading partners? The 4 G’s, in this case, are the essential tools used by manufacturers which drive the success of a supply chain.

Implementing and Communicating Sustainability Attributes in Food Product Development and Labelling with PLM

Consumer food needs are moving up in the Maslow’s Hierarchy of Needs - from satisfying their physiological needs to food safety to social esteem, and even self-fulfilment. As consumer perception of healthy eating wavers throughout their lifetime according to knowledge, experience, and particularly, the type of information they gain, food trends, climate crisis, and health issues allow for varying perspectives. Consumer`s income elasticities and demand for food quality attributes are influencing the growth in the food sector. In recent years, this has led to the significant increase in demand for the special range of quality attributes.

Innovative PLM aids ERP barriers to success

Food industry under pressure The food and beverage industry generates billions of dollars in revenue every year, but the truth is that profit margins are razor-thin, and manufacturers need every conceivable advantage to thrive in an exceptionally competitive marketplace. Smart manufacturers seek to expand their market share by participating in the global distribution – but increasingly stringent regulatory compliance challenges can make the exportation of products an adventure in frustration. Add consumer demands for comprehensive ccurate product information and their distrust of brands

Making innovation easier in Food and beverage Industry

Recognizing Challenges and Opportunity Embracing and driving change with innovation is arguably the best solution for the most rapidly growing challenges in the food and beverage industry, while thin profit margins and competition are the major growing issues. Change is all about integration with innovation. It is important to integrate the latest technology, digitalization, trends and sustainability with evolving consumer (market) needs with a flavor of innovation. Driving innovation with integration in the food

Increase communication, cash-flow and compliance with cloud PLM

Prime efficacy is in the PLM cloud To prosper in an exceptionally competitive market, food and beverage manufacturers must manage their resources carefully – and resource management begins and ends with data. Organizations that work with stale, incomplete or inaccurate data may experience less than stellar calculations, simulations, compliance and formula processes. Recent reports from reputable research organizations indicate that more than 70 percent of manufacturers currently employ cloud-based solutions. While the broader based industrial

Using product data management to meet – and exceed – consumer demands for individualized food.

There is no ‘one-size-fits-all’ when it comes to food…not anymore. Industrialization and globalization have greatly contributed to consumer food trends and preferences. Growing consumer demand for transparency in food products continues to have a significant impact on food supply chains. Moreover, consumer purchase factors have grown to prioritize convenience, clean, taste, trendy, sport, novelty, healthy, fresh, safe and environmental sustainability.

Digitizing to boost productivity and profitability

Savvy food and beverage manufacturers know that our industry is constantly reinventing itself. More than 30,000 new products are introduced by food and beverage producers every year. According to the USDA, the new products are primarily snacks, bakery foods, sauces, dressing and condiments. The greatest challenge for manufacturers is to shift quickly to meet consumer demands – while decreasing costs, adding value and empowering enterprise-wide innovation. It can be difficult to maintain speed, flexibility, quality and innovation while keeping an eye on bottom line costs and net profitability...

Power of the Cloud

What, exactly, is the cloud and why do I care Cloud computing is the delivery of services – from applications to storage – over the internet, with a ‘pay-as-you-go’ feature. Rather than owning the hardware and infrastructure headaches, cloud participants enjoy access to all of their data via licensing and subscription agreements. Food and beverage producers are moving to cloud-based options for product data management in droves – a few of the reasons are: Infrastructure challenges are eliminated, no downtime for maintenance or updates that freeze production Upfront costs are drastically reduced Scalability is enhanced

Consistency in labeling crucial for consumer safety

Enhanced labeling technologies offer worldwide benefits Comprehensive, accurate product data provides consumers with the facts they need to make the right choices for their family - and they reward companies that provide the most information with their food dollars and long-term brand loyalty. More than any other tool, innovative, end-to-end software solutions, like PLM and PDM, are the surest way to stay flexible and protect consumer rights to complete, accurate information on product labels. Comprehensive data capabilities offer important benefits to any food and beverage organization.

New product innovation for F&B producers

The food and beverage manufacturing industry generates billions of dollars in revenue every year – and is poised for explosive growth as consumer demands for clean labels, traceability and sustainably sourced products continues to intensify. In order to increase market share, organizations must operate at optimal capacity – that means quick to market reaction and employing best practices to streamline operations while embracing every opportunity to obtain a competitive advantage. Transparency supports innovation and

Green label transparency and clean eating

Transparency builds consumer trust ‘Eco-friendly,’ ‘green’ and ‘clean eating’ can be subjective terms when it comes to the food and beverage industry – that is why it is imperative that manufacturers provide comprehensive, easy to understand information on product labels - so that consumers can draw their own conclusions. Consumers are smart, when it comes to food and healthy eating, they want to make the best decision for their family - but they can’t do it alone. It is up to food and beverage brands to improve their labeling strategies and deliver the information

Food quality versus food safety

Finding the essential balance Defining food safety and food quality is nearly impossible. From consumers, to regulatory agencies, to food manufacturers – the answer depends on who - and what - you ask. For example, food safety is sometimes defined as anything present in food that could possibly be harmful to consumers, like biological, chemical or physical objects. End-user preparation is a challenge; many consumers create a hazardous environment while thawing or cooking their food. But it’s not always about end-use prep - food safety also includes

Fighting Food fraud with data

Food fraud and food safety are among the top concerns for food and beverage manufacturers – and for consumers. Industry leaders have deployed process solutions to support supply chain transparency and traceability, in an effort to ensure the safety and authenticity of their recipes and formulations. Particularly in an age where farm-to-fork labels are indicative of the freshest, most healthy products, it has become essential to track and trace ingredients to their source, and to maintain a clean

PDM Empowers Industry 4.0

Competitive advantage for F&B producers Producers in the food and beverage industry seek competitive advantages – they have no choice; individual product profit margins are notoriously thin. In order to achieve trustworthy food safety, accurate labeling, traceability and transparency throughout the global supply chain, manufacturers must digitize and empower their teams with Industry 4.0 integrated process solutions that deliver strategic competitive benefits. Product data management

Top 3 Reasons F&B Producers Need SaaS PLM

Where’s the ROI The use of software as a service, or SaaS, has increased rapidly in the food and beverage industry. Many reputable studies indicate that SaaS deployment has more than doubled in the past year. F&B producers have unique challenges, and they need to be very light on their feet if they are to meet the fickle demands of consumers – while complying with ever-changing global regulatory compliance requirements.

Embrace Organics

The most current trend for consumers is organic products, because they represent clean, sustainably produced foods. Demand for organic products among shoppers continues to climb, in fact, U.S. organic sales reached a milestone $49B in 2018 - an increase of 6.4 percent from the previous year, signaling the fact that this particular trend is here to stay. The preference for organic products is part of a larger expectation among consumers who are increasingly health conscious. Many shoppers will not purchase food without access to comprehensive, accurate product information. They demand to know if antibiotics or hormones were fed to their poultry, beef or pork – and if the production process was ecofriendly and

Product Data Management 4.0 – these are the trends

With the advancement of the digital transformation, one fundamental assumption has become prevalent: data is the oil of the 21st century. Anyone who manages to collect, read out and use data effectively is well on the way to becoming a sustainable company. For the food industry as well, this means spending more time and money on proper product data management. But PDM is not equal to PDM. Finding the right system can mean a lot of work. First of all, there are some key questions to answer: Which data is relevant? Which data help your own insights, which help the customer / customer? Which data increase the costs of quality management, which lower it? And how can compliance be maintained?

Dynamic growth predicted for baked goods industry

Growing consumption trends for baked goods – think pastries, muffins, quiche, biscuits and muffins – show immense untapped growth potential for global distribution as consumer demand for these product skyrockets. Market insights indicate packaged baked good demand is a direct result of U.S. influence regarding culture and convenience foods. According to growth trends forecast, the total market for bakery products is expected to reach 530 billion USD by 2023. From innovative new products, formerly inaccessible health-conscious choices and eclectic flavor combinations to workplace lifestyle changes that enhance the need for consumers to eat

Deep Dive: PLM Innovation is Essential for Sustainable Growth, Stability

More than 30,000 new food products are introduced in the US every year, and according to research conducted by the business school at Harvard University, nearly 80 percent fail - but the study indicated that it’s most often not the product, it is a lack of innovation in the preliminary ideation and an inability to nurture the product through its lifecycle.

PLM software delivers ROI

The simple fact is that every time you scrap or revise a project or process, you lose money. Recreating lost, fragmented or untraceable documents instead of focusing on the development of new products can cost your company thousands of dollars in hard costs - as well as soft costs, like staff time and efficiency. Continually updating product data across multiple BOM spreadsheets is time-consuming

Product Data Management 4.0 – The Importance of Digital Transformation for QM in the Food Industry

Do you know the biggest adversary of digitization? He is white, can weigh tons and usually needs a lot of space. We are talking about paper. Many food companies continue to rely on manual and paper-based data storage and product data management (PDM). This is neither sustainable nor able to meet the requirements of Industry 4.0

No More Silos – Overcoming the Hurdles of Legacy Systems

Legacy systems can’t support innovation, compliance or labeling best practices The failure of legacy systems to keep up with the rapidly changing needs of food and beverage manufacture rs is entirely predictable – in fact, most of the producers who employ these systems are aware that they are living on borrowed time and simply delaying inevitable problems. Unfortunately, more than 60 percent of manufacturers who have legacy PLM systems indicate that they are basically stuck waiting for

Closing the Gaps with PLM

Innovation – rapidly responding to consumer demands and market trends – is the only way for formula-based food and beverage manufacturers to achieve success and continued, sustainable growth. Organizations do not intentionally shed their commitment to innovation, rather, they lose the culture of entrepreneurial innovation, one date at the time. Often this happens as the company begins to grow; research departments that were once agile - quick to take chances and pivot to innovative new products – are suffocated by fear of product launch failure.

Labels: organic, ecofriendly, sustainable – How do you know?

Consumers, especially Millennials, Gen Y and Gen Z have a very different relationship with food than previous generations. They want to know exactly where their food came from, what is in it and if it was produced in an environmentally conservative fashion. They want to know if the raw materials were grown sustainably, if the product was produced according to the principles of fair trade or if the food does not harm the marine ecosystem. In addition, a number of claims can be done in regards to dietary information such as

How to gain executive support for your PLM adoption

CEOs are traditional big-picture thinkers; they may not be as focused on innovative digital technologies as their front-line employees who struggle to innovate while using disjointed, out-of-date technology. An expanding gulf between many front-line employees and the C-suite in the recipe-based food and beverage industry makes it nearly impossible for lower-level decision makers to advocate for the technologies they know will improve the lives of employees and customers

Consumer demands for local, natural organic products skyrocket

Shoppers have spoken – they want organic, natural, locally produced products and are quite willing to pay more for them. A recent survey reports that fully two-thirds of consumers in the U.S. look for this information on their product labels – and nearly 60 percent say that they will not purchase products that do not have explicit, comprehensive product sourcing information on the label. Label inconsistencies However, many shoppers report being confused by definitions

Baking industry facing growth challenges

Unique challenges Food engineers and technologists in the baking industry are struggling to keep up with consumer demands. Health conscious customers demand a wide variety of delicious baked goods – but they also want healthy, organic ingredients. Unlike many subsets within the recipe-based food and beverage industry, consumers say that baked goods are only exceptional when they are freshly baked. Bakers face unique challenges with the shelf life of their ingredients. Their products are

Millennials – Smart Eating and Label trust

Nearly 40 percent of millennials say that they will switch brands for transparency – so food producers that provide them with the most accurate and transparent information win. Innovative PLM formulation and labeling process solutions as a single source of truth are the surest path to deliver complete, accurate information. Label trust must be a top priority - millennials make up more than 30 percent of our population and there are 80 million of them. They are target consumers in every industry, but particularly for food and beverage producers, they are a crucial capture for sustainable growth.

Recycling of packaging waste from the food and beverage industry in Belgium

An old television set carelessly tossed out in the street. Full blue garbage bags are lost in the forest. Cans, plastic bags and other packaging in the middle of a field. People are inspired with limitless ways to dispose of their trash – and it doesn’t seem to matter to them that they are not only destroying the environment, but also risking hefty fines. Proper waste disposal is not only a problem for households, but also for businesses in the food and beverage industry, especially, when they export their products to countries like Belgium.

Celebrating ethics and integrity on National Compliance Officer Day

Many companies choose to hire internal compliance officers or chief ethics officers to fill crucial roles. Compliance team members are not only responsible for company-wide compliance, they are charged with protecting the company from any type of regulatory issues that may arise – quite simply, they make a significant contribution to overall compliance with food and beverage-related regulations. Regulatory compliance involves exemplary attention to detail, fast reaction times and ethical conduct in a constantly changing environment.

Success Stories – PLM best practices

Research, development and design of a new product does not happen overnight…simulations, trials and testing must confirm that the recipe is ready to go to market and has been produced as cost-effectively as possible. Quality, standards, market research and intelligent design are all part of the process – innovation is nearly always collaborative and can be a very challenging proposition.

The demands of savvy consumers

When it comes to their food, consumers have become far too savvy to settle for less. They demand – and deserve – healthy, farm-to-fork options that can be traceable with a single source of truth.

Rule-consistent product information

Nearly 15 million Americans suffer from some sort of food allergy - gluten intolerance, peanut, pine nut anaphylaxis – that includes 6 million children. Therefore, having a digital product data management system is an absolute must for fast and easy documentation of all rule-consistent product information.

Safe, accurate labeling with compliance guide and supplier’s guide

Consumer confidence is a manufacturer’s most valuable asset. The best way for consumers to learn about food safety is by reading the label. The accurate end-to-end information that is provided on the label lists all important information related to nutritional values, ingredients, origin, and manufacturer.

Authenticity, fraud and food safety

According to the National Institute of Health, U.S. National Library of Medicine, food fraud is a global epidemic. Deceitful practices in the food and beverage industry costs millions of dollars, disrupt the market for a myriad of products, erode consumer confidence in manufacturers and damage the reputation of entire sectors of the industry.

The balance between innovation and compliance

Innovation or compliance, which comes first? Many food engineers and food and beverage manufacturers struggle with restrictive compliance regulations – others with driving innovation without running afoul of compliance procedures.

Scientific debate around risk assessment of packages with food contact

Urban gardening, open source gardens or a simple vegetable patch in your backyard – the trend is toward do-it-yourself farm-to-table living. Regardless of whether it is the obligatory basil pot, tomato plants on the balcony or a raised garden bed with potatoes, cucumbers, onions and carrots - many people have stopped trusting industrial and mass-produced grocery store goods. Food and beverage manufacturers are facing their greatest challenge - risk assessment of materials that come into contact with food.

A smaller ecological footprint

Most people associate ecological or carbon footprints with lifestyle factors, like carbon dioxide emissions from transportation and the consumption of electricity, water, oil and coal. Food engineers and recipe-based manufacturers who understand the buying habits of consumers know that their consideration of our natural resources and the size of their footprint is a decisive factor for most customers.

#PIMcontinued… 10 reasons to improve data quality

#PIMcontinued…10 reasons to improve data quality

PIM – 10 reasons to improve data quality

The purpose of product information management is to optimize the quality of product data on a single platform, improve communication with consumers and increase sales. PIM provides the platform for product information distribution across channels.

Global regulatory compliance

Imagine searching for a specific regulation. Start in your library, you probably have access to at least 90,000 books – but where do you begin? You could waste hours or even days trying to locate the rules that apply to your products. This is not an unrealistic scenario for manufacturers in the food and beverage industry, this is part of their daily work.

Managing Food Safety Data Using LIMS for Food and Beverage Industry

Food and beverage manufacturing is a global endeavor. Products may be manufactured in one facility, but the ingredients going into said products most likely come from around the world, and eventually finished products will end up back in the global marketplace. The nature of a global food supply chain dictates the need for inspection, quality control and safety protocols. The challenge that food and beverage processors face is the need to comply with not only their local regulations around food safety, but also those of the countries to which they sell to.

PLM – the right packaging and design management

When it comes to managing and designing food product packaging, the seamless calibration of interdepartmental communication is a must. Therefore, investing in a product lifecycle management (PLM) system can be quite beneficial.

Centralizing Information Management in the Food and Beverage Industry: A Case for LIMS Applications in Food Safety and Quality Management

Real-time access to and centralization of data is an essential element in any efficient and safe food and beverage processing environment. The challenge faced by many food and beverages processors is the lack of industry-specific technology that tailors to their operational and industry-specific needs. The manual pen-and-paper methods used widely across the industry to keep track of incoming, outgoing and internal operational data is needing to become obsolete due to the pressures from regulators, legislators, and business partners for data traceability, access and accountability.

Compliance in the Food and Beverage Industry

This trend marks the last two years: food and beverage companies that sell their products without packaging. In Germany, there are about 70 companies like these, and the trend is increasing. However, this is still a niche market, as packaging with product information is an important factor for consumers when deciding whether or not to purchase the product. Compliance plays an important role and is key for guaranteeing that the labels and product information meet customer demands. Read more here about meeting compliance and how that benefits manufacturers in the food and beverage industry.

Towards globally uniform blockchain-based PDM/PLM services and solutions

The availability of coherent and uniform data structures remains one of the pressing issues in globalization, effective supply chain utilization, competition and "oversight." The food and beverage industry depends on accurate and timely manufacturing data, which must be increasingly available and accessible on a global level while remaining secure. Additionally, the industry inhibits a strong push toward "traceability" of the specifications, ingredients, sources and processes along the complex supply chain spanning across continents, regulatory regimes and traditions.

The new FDA labeling requirements – Here is how you can meet international standards

If you work as a manufacturer in the food and beverage industry, you know that there is a copious volume of legal guidelines and requirements to adhere to. Particularly in terms of food product labels, specific national and international legislation governs the sale and distribution of goods. This is due to the informed consumer, the driving force in this industry. Whenever dietary habits change, so do product labeling specifications, the most recent example being the enactment of a new US-American Food and Drug Administration (FDA) regulations to come into effect on July 26, 2018, which will necessitate manufacturers to do complete redesign of their labels.

Towards global Food & Beverage PDM security requirements

Just as cyberspace spans across market and regulatory regimes, continents and from island to island, so do vulnerabilities and attacks. In cyberspace, all businesses are in the same boat when it comes to security, yet each is subject to different regulatory requirements. If they could do it today for local markets, to truly benefit from global supply chains and be prepared for possible mergers and acquisitions, it makes a lot of sense for global businesses to ensure that in the least, their product lifecycle management security is aligned with global data security standards.

SaaS or Cloud – Approaching global business regimes for food and beverage companies through distinctive PLM infrastructure options

Security is becoming an increasingly multi-faceted and multi-dimensional concept in global cyberspace. Product data management is a key asset in the manufacturing business, and now, more than ever, in the era of global business supply chain structures in cyberspace, the security of product data and its lifecycle becomes all the more crucial. Outdated border-based security frameworks, strong defenses and internal black-box mechanisms may no longer be able to serve the needs of global businesses. Regulatory complexities, such as recent trade embargo rulings, for example, directly impact global supply chain management of the food and beverage manufacturing sector and their inherent PLM systems.

Five Data Strategies for Effective Supplier Collaboration

Supplier Relationship Management (SRM) is an integral part of a business's overall operational strategy. To be successful, businesses need to learn to adapt to changing geographical and network boundaries to effectively collaborate with partners in the supply chain.

On the imperialist implications of food and beverage of global blockchain models

Blockchain-based global product lifecycle management systems, together with other cyberspace phenomena, are seeking totalitarian dominance over supply chains, creating a detailed data model product lifecycle starting from before the ingredients existed to well into future potential events, as these events can be predicted based on comprehensive learned and collected data concerning the particular item or its ingredients.

Competitive advantage through ISO 27001 security certification for Master Data Management

According to an ISO27001 Global Report 2016, over half (56%) of the respondents indicated that gaining a competitive advantage was a major motivation for them to acquire certification. SpecPage's ISO27001 certification will definitely be a push for customers to implement SpecPage products and services, including the Product Lifecycle and Data Management (PLM, PDM) software and services. A key fact to point out is that ISO certifications are granted to companies rather than specific products or services.

How to Comply with Food Contact Regulations

Food is seldom safe from contaminants, they can be from human error or hazardous materials. Food contact materials such as cutlery, crockery, cartons, packaging, and kitchen equipment often contain microorganisms and chemicals which can detract from food quality and make it unfit for consumption. When this happens, food fails to meet the requirements set out by global governing bodies in the Food & Beverage industry.

More efficient product development for resource-strapped times

Heal the world and make it a better place. That was pop icon Michael Jackson's vision in 1992. Now, 25 years later, his message is more urgent than ever. After decades and centuries of waste, people are now faced with diminishing natural resources that will eventually be depleted from the planet. This will be a certain demise unless people and industry change their behavior. What do increasing customer demand and product complexity have to do with this issue? Read more in this blog and learn how and why more efficient product development with intelligent software can be a solution to this pressing problem.

Cloud- or SaaS-hosted PLM for the Food & Beverage Industry?

Supply chain security is a hot topic today, and various recent cyberattacks have indeed used vulnerabilities found in supply chain processes and providers to gain entry and access to their main target. Product lifecycle management services and associated tools play a key role as enabler for competition and as a frontline defense to safeguard essential business assets.

GDSN® Initiative – Are you ready to boost your sales and break into the Chinese marketplace?

Alibaba Group was established in 1999 with a mission "to make it easy to do business anywhere." The founders started the Alibaba Group to champion small businesses, in the belief that the Internet would level the playing field by enabling small enterprises to leverage innovation and technology to grow and compete more effectively in the domestic and global economies.

Industry 4.0 – opportunities through new technologies

Food producers are under pressure to meet changing consumer demands and purchasing behavior. At the same time, new products must meet compliance guidelines both on the local and international level. The US-American Food Safety Modernization Act (FSMA) and the EU’s LMIV represent just two food standards that exist around the world that must be met when trading products globally. To this end, effective data management and seamless documentation of all processes throughout the entire product life cycle must be in place – from research, development, and finally, to the supermarket shelf.

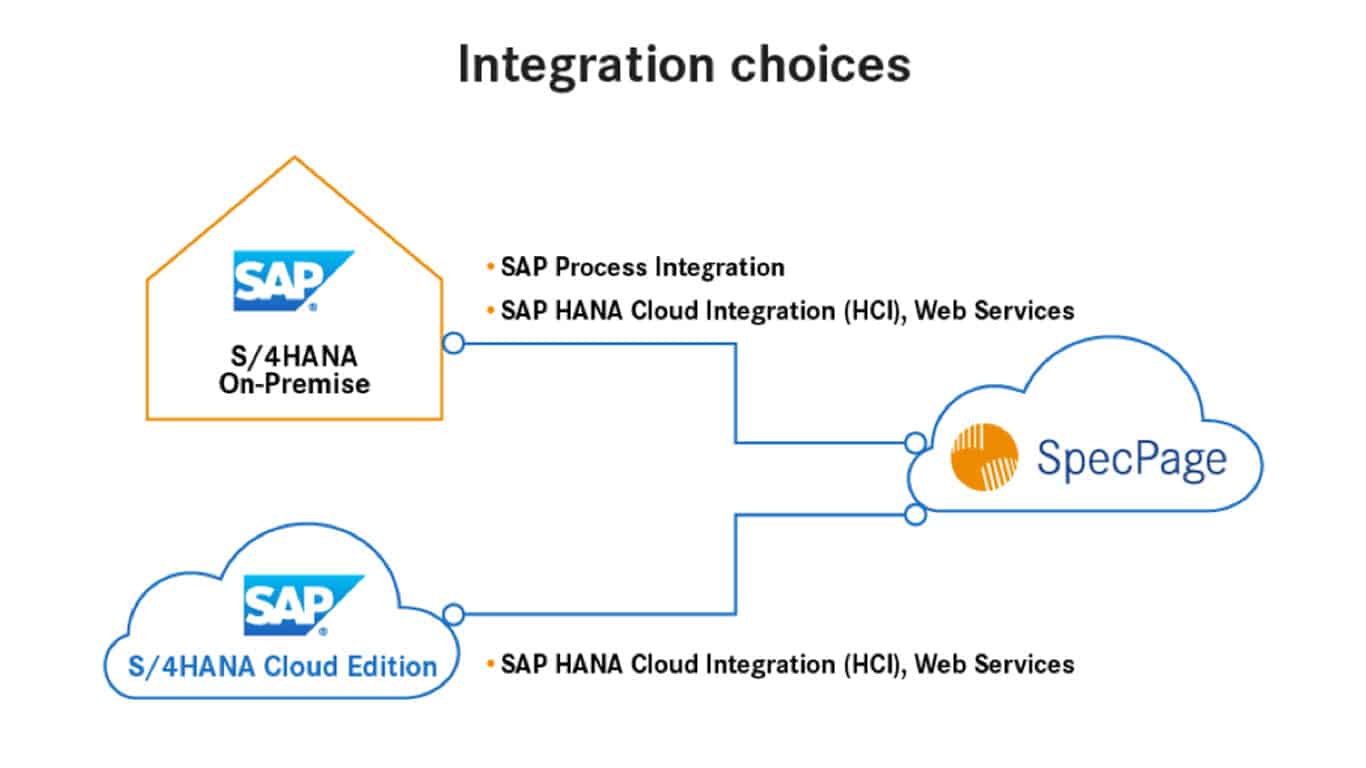

How S/4HANA (ERP) goes hand in hand SpecPDM to make the journey smoother

SAP S/4HANA is an ERP suite and is used to manage financials and reporting processes. These processes basically revolve around activities of accounting, sales forecasting, manufacturing planning and execution, as well as support and shipping logistics. The ERP suite also assists organizations in planning orders and tracking profitability by providing manufacturers with a real-time visualization of their financial status. With an ERP system in place, companies can track orders from receipt to production and delivery in order to gain a better understanding of inventory levels, delivery lead times and production bottlenecks.

How Industry 4.0 is changing the food industry

Placing Industry 4.0 at the forefront of the digital agenda in all manufacturing industries and thereby increasing competitiveness is a matter of course and clearly also applies to the food and beverage industry. Changing consumer behavior and legal regulations, as well as increasing specialization means new challenges for the industry. Even though many manufacturing plants have already automated their processes, there is still often the need for structural integration of a comprehensive data model. The digital integration of plant-wide processes offers innovative solutions in this vein. What Industry 4.0 means for the food and beverage industry, where to tap opportunities and the concrete measures to implement in is the topic of this article.

Integrating PLM/PDM Software into SAP

Nothing beats that fresh taste of an earned drink in the wake of a monotonous day. In any case, when that one most loved drink is out of stock, sheer dissatisfaction sets in quickly. Eckes-Granini, with annual revenue of 900 million Euros, has made it its central goal to guarantee that no client’s thirst is left unquenched. By tapping into its high volume information sources, the German producer and supplier of numerous brands, Granini, Eckes Traubensaft, Pago, Yo, FruchtTiger and Hohes C, amongst others is picking up knowledge of its every day operational coordination, which is instrumental in taking care of customer demand throughout its retail channel. The same holds true for most of the well-known corporations in the world.

PLM: A Key Enabler for Food Label Digitization (Part II) – Challenges and opportunities

For manufacturers, updates and changes to food labeling regulations represent challenges as well as opportunities. They have the opportunity to reinforce customers’ confidence in their brand by reacting to updates swiftly, particularly when the new packaging emphasizes a healthy message. There is also the risk of products seeming less healthy as a result of now mentioning ‘added sugars’ or higher calories, which can drive customers to a rival offering healthier products. The only response is to reformulate products to retain their appeal among consumers.

PLM: A Key Enabler for Food Label Digitization (Part I)

Product lifecycle management (PLM) is a strategic approach that applies a consistent set of business solutions in support of the creative collaboration, management, dissemination and the use of product definition information across the extended enterprise from concept through life – integrating people, processes, business systems, and information.

Managing and Mitigating Risk in The Food & Beverages Industry Using Technology- Enabled Risk Management

The Food & Beverage Industry is one of the most dynamic industries around. Just as in the world of fashion, the food sector too experiences constant evolution. The changing industrial climate makes this industry particularly challenging for manufacturers, suppliers and retailers alike.

The Food & Beverage Industry is Heading Towards Greater Transparency with Green Labels

Consumers today are better informed about product safety and purity than they were a decade ago. Today’s consumers are increasingly conscious about their purchase decisions and are increasingly contentious about only buying food that is safe and healthy.

How to Find Out if an Investment Guarantees a Good ROI

Imagine you wish to invest in a company’s shares today. But before you actually invest your hard earned money into an unknown venture, you decide to evaluate your future returns. These returns can be classified as good or bad depending on both the company’s future performance and the amount you have invested today. If the returns you receive are higher than what you have invested or are planning to invest, then the Return on Investment or ROI is high. However, if the returns you receive are lower than what you invested or intended to invest, the ROI is low.

Gluten Allergy is a Rising Issue in Today’s Society – 10 Innovative Ideas for Product Development

Bread, noodles, cornflakes – imagine a world where you can’t enjoy these tasty treats. This is an everyday reality for people with gluten allergies. Recent research revealed that 1 in every 133 suffers from gluten allergies worldwide, meaning that a large chunk of the world’s population is unable to digest gluten in any form.

Food Industry 4.0 – Revolution or Evolution?

The face of the Food & Beverage industry is changing. With the Internet of Things (IoT) technologies, cloud computing, cognitive computing and virtual reality helping bridge the gap between the cyber and physical realms, there is greater innovation and automation in the Food & Beverage industry.

How to Improve Your Product Lifecycle Management from Supplier to End-Consumer

Product optimization only yields the best results when there is a focused attempt at controlling the associated costs and quality, from product ideation and onward. This is where product lifecycle management comes into play. By exerting proper controls and by managing all the processes and activities involved in new product development, organizations can ensure that the final product released to market is of high quality and low in cost.

Nutrition Labels – What Customers Want to Know and How Manufacturers Can Ensure Compliance

Consumers have become more conscious about the contents of the products they consume. They want to know what is in the product, when it was manufactured and how long it will remain fresh, the amount of sugar, calories, grams of fat, and whether the food or beverage is genetically modified, natural or organic. How can manufacturers engaging in recipe-based production respond to evolving consumer preferences?

Digitization and Online Distribution of Product Information – publish to GDSN directly from your ERP system

Availability of information in the Food & Beverage industry is extremely important, given the nature of the products that are being manufactured and consumed. In fact, European Union (EU) regulations specify that customers are entitled to access the same information online that is provided to them by retailers when making in-store product purchases. To implement these regulations, companies need to follow a standardized and focused approach when recording and uploading product information online.

Optimizing Product Development in the Food & Beverage Industry

The Food & Beverage industry is growing at an unprecedented rate. With new players entering the arena each day, the need for optimizing product development rises. Companies reap multiple benefits when processes and activities involved in new Product Development and Product Management stages are controlled and made operationally efficient.

Food and Safety – 5 Essentials for Food Specification Management Guaranteeing Food Safety and Exceptional Product Quality

Food safety is a top priority for anyone operating in the Food & Beverage industry. Only when companies consistently provide safe and quality will customers make repeat purchases. Without standardized procedures in place, companies may be unable to control the quality of their end-product. If consumed, these contaminated products will result in the consumer developing a host of health problems. If left unchecked, mistakes in the product manufacturing process can lead to fatalities.

Consistent Product Data Management in the Food and Beverages Industry

Ensuring product quality is one of the most important activities that businesses need to engage in. The first step here is to ensure that there is consistent reporting of all processes followed and all materials used. Data management is useful in keeping all product-related records up-to-date.

Don’t Let Compliance Regulations Become an Issue within the Lifecycle of Your Product

In the Food & Beverages industry, compliance is of extreme importance because of the nature of the products manufactured. Food and beverages directly affect the health of the consumer. Businesses have a moral obligation to be aware of what goes into the production and sale of the products.

Issues of Consumer Product Information Transparency

Many regulatory bodies and companies struggle with product information transparency. There have been many consumer complaints in various countries, with angry customers seeking full product information. With consumer safety in mind, federal agencies are now requiring companies to provide relevant information in a timely and efficient manner as to avoid problems in the future. The Food and Drug Administration (FDA) has a new rule for the Food & Beverages industry in the United States

Product Lifecycle Management in F&B – Five Cornerstones for Optimisation

Companies in the food and beverage (F&B) industry face the challenge of innovating to meet the evolving needs of consumer segments, staying compliant with complex regulations, and maintaining their competitive edge by ensuring consistent quality and improving time-to-market. A company that manufactures salty potato chips, a perennial favorite, operates in a saturated market where healthier (ex: baked chips) or better-tasting (ex: salty with a cheesy twist) or better marketed (viral or extremely popular ads

Food Product Label Service for Europe

SpecPage launches Food Product Label Review Services for European Markets.

GDSN Major Release 3

With GDSN Major Release 3, you'll be able to provide richer product information, adapt to regulatory requirements, support industry-specific functionality, improve data quality and increase speed to market. Are you ready?

Keep in touch with SpecPage

Contact us to get more information about our products and services.

Food for Thought E-Book

Learn how to build a foundation that supports change and spurs growth!